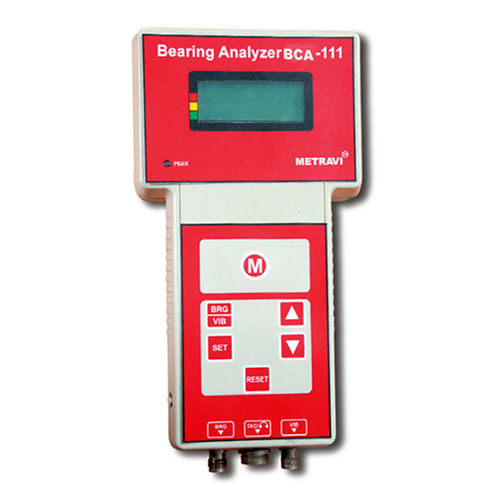

Metravi BCA 111 Bearing Condition Analyzer and Vibration Meter

Price 146497.00 INR/ Piece

MOQ : 1 Piece

Metravi BCA 111 Bearing Condition Analyzer and Vibration Meter Specification

- Accuracy

- 5% of reading 2 digits

- Display Type

- LCD with Backlight

- Test Range

- 0.01 199.9 mm/s (velocity); 0.1 1999 mG (acceleration); 0.0011.999 mm (displacement)

- Automation Grade

- Manual

- Humidity

- 85% RH (non-condensing)

- Interface Type

- USB (for charging)

- Equipment Type

- Bearing Condition Analyzer and Vibration Meter

- Operating Voltage

- 3.7V (via Lithium Battery)

- Measuring Range

- Velocity: 0.01199.9 mm/s, Acceleration: 0.11999 mG, Displacement: 0.0011.999 mm

- Response Time

- Instantaneous

- Features

- Bearing quality indication (Good/Bad), ISO standard vibration evaluation, Data Hold, Auto Power Off, Backlight

- Resolution

- 0.01 mm/s, 0.1 mG, 0.001 mm

- Frequency

- 10Hz 1kHz (overall); Bearing Frequency 1kHz 10kHz

- Application

- Bearing condition detection, mechanical vibration measurement, machine maintenance

- Power Supply

- Rechargeable Lithium Battery (3.7V, 1500mAh)

- Temperature

- 0C to 40C

- Mounting Type

- Handheld

- Usage

- Portable measurement and analysis

- Machine Weight

- About 500g (with battery)

- Control Mode

- Manual

- Operating Principle

- Vibration analysis by frequency spectrum and bearing algorithm

- Dimensions

- Approx. 172 x 65 x 33 mm

- Transducer Type

- High-sensitivity piezoelectric accelerometer

- Probe Type

- Magnetic and contact probe included

- Sampling Rate

- 20k samples/sec

- Standards Compliance

- Conforms to ISO 10816

- Battery Life

- Approx. 8 hours continuous

- Alarm Function

- Good/Bad bearing status alert

- Data Output

- No data logging (instant readings only)

- Accessories

- Carrying case, probe, charger, user manual

Metravi BCA 111 Bearing Condition Analyzer and Vibration Meter Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Metravi BCA 111 Bearing Condition Analyzer and Vibration Meter

- Micro-processor based diagnostic tool

- Direct Indication of machine condition in terms of good-reduced-bad

- Mechanical Condition of Bearing

- Lubrication condition of Bearing

- Damage Severity readings for rolling bearings.

- Non-Contact measurements of rotational speed

- Vibration Severity measurements according to ISO recommendations.

- Bearing Tester Function Range 0 to 99dBpv

- Vibration Range 0.1 to 99.9 mm/s RMS

- Laser Tachometer range up to 20000 RPM

- Bearing Probe, head phone, Accelerometer, tachometer probe, manual, battery and carrying case

Advanced Vibration Analysis for Maintenance

Employing vibration analysis through frequency spectrum and specialized bearing algorithms, the Metravi BCA 111 helps you assess the condition of rotating machinery. Early detection of abnormal vibration patterns enables planned maintenance, mitigating severe breakdown risks and optimizing operational efficiency. Its robust analysis capabilities are indispensable for mechanical and maintenance engineers.

User-Friendly Design and Portability

With an ergonomic, lightweight build and a comfortable handheld design, the BCA 111 is portable for field operations. The backlit LCD ensures clear readings even in dim environments, while instant response time and data hold features make it intuitive to use. Its rechargeable battery offers about 8 hours of continuous testing, supporting extensive maintenance rounds.

Comprehensive Accessories and Compliance

The instrument is supplied with a magnetic probe, contact probe, carrying case, charger, and user manual, ensuring convenience and readiness for various test scenarios. Compliance with ISO 10816 assures you of reliable, standardized vibration evaluation. Its dual probe system enhances flexibility for different machine types and components.

FAQ's of Metravi BCA 111 Bearing Condition Analyzer and Vibration Meter:

Q: How does the Metravi BCA 111 determine the condition of machine bearings?

A: The Metravi BCA 111 uses a high-sensitivity piezoelectric accelerometer and advanced algorithms to analyze the vibration frequency spectrum. Based on ISO 10816 standards, it evaluates bearing condition and provides an immediate Good/Bad alert, guiding users toward timely maintenance actions.Q: What types of machines or components can the BCA 111 be used on?

A: This analyzer is suitable for rotating machinery equipped with bearings, such as motors, pumps, fans, and compressors. Its magnetic and contact probes allow for versatile application across various industry sectors in mechanical maintenance.Q: When is it recommended to use the Metravi BCA 111 for vibration analysis?

A: It is best employed during regular maintenance checks, after repairs or installation of machinery, or whenever unusual noise or behavior is observed. Regular monitoring can identify deteriorating bearings before they result in expensive breakdowns.Q: Where can the measurement device be typically used?

A: The compact and lightweight design allows technicians to use the BCA 111 in field environments, factories, workshops, and industrial plants across India and other regions. Its portability ensures suitability for both on-site inspections and routine facility surveys.Q: What is the process for performing a vibration measurement with this device?

A: To conduct measurements, simply select the appropriate probe, secure it to the machine, and power on the device. The vibration data appears instantaneously on the backlit LCD, and the Good/Bad indicator simplifies interpretation. The auto power off and data hold features further facilitate efficient field use.Q: How long can the BCA 111 operate on a single charge and how is it recharged?

A: The device operates for approximately 8 hours continuously on a full charge. It uses a rechargeable 3.7V lithium battery and can be conveniently charged via its USB interface using the supplied charger.Q: What are the benefits of using the Metravi BCA 111 in regular maintenance routines?

A: Implementing the BCA 111 helps detect bearing issues early, avoids unscheduled downtime, and prevents costly repairs. Its instant feedback allows maintenance teams to make quick decisions, enhancing equipment reliability and operational safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vibration Meters Category

Metravi Dual Channel Vibration Meter

Price 86317.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial equipment, maintenance, research

Application : Vibration monitoring and analysis

Frequency : 10Hz 10kHz

Resolution : 0.1 m/s, 0.1 mm/s, 0.001 mm

Metravi PVB-820 Pen Type Vibration Meter

Price 17877 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Measure Acceleration, Velocity, Displacement

Application : Industrial

|

METRAVI INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry