Metravi DTC 200 Single Channel Temperature Controller

Price 2006.00 INR/ Piece

Metravi DTC 200 Single Channel Temperature Controller Specification

- Measuring Range

- -50C to 1999C (sensor dependent)

- Application

- Temperature control in process automation, industrial ovens, plastic machinery

- Accuracy

- 0.5% of FS 1 digit

- Temperature

- Operating: 0C to 50C

- Port Size

- Panel Cutout: 76 (W) x 76 (H) mm

- Response Time

- < 1 second

- Power Supply

- 85V AC to 270V AC, 50/60Hz

- Automation Grade

- Automatic

- Display Type

- Dual 7-segment LED

- Humidity

- 10% to 90% RH (Non-condensing)

- Operating Voltage

- 85V to 270V AC

- Mounting Type

- Panel Mount

- Frequency

- 50/60Hz

- Resolution

- 1C

- Features

- Relay/alarm output, display for PV & SV, compact design, autodetect sensor

- Equipment Type

- Digital Temperature Controller

- Usage

- Industrial, Laboratory

- Machine Weight

- Approx 250g

- Control Mode

- PID (Proportional-Integral-Derivative)

- Alarm Output

- 1 Alarm output (programmable)

- Cut Out Size

- 92 x 92 mm

- Ambient Temperature Range

- 0°C to 50°C

- Model Number

- DTC-200

- Dimensions

- 96 (W) x 96 (H) x 52 (D) mm

- Protection

- IP30 (front panel)

- Display Color

- Red (PV), Green (SV)

- Compliance

- CE Certified

- Input

- Thermocouple (J, K, T, R, S) or RTD (Pt100)

- Setpoint

- Single Setpoint

- Relay Output

- 1 Relay SPDT 230V AC, 5A

- Sampling Rate

- 4 samples/sec

- Indication

- Process Value (PV) and Set Value (SV)

- Storage Temperature Range

- -20°C to 70°C

- Sensor Type

- Selectable: Thermocouple/RTD

Metravi DTC 200 Single Channel Temperature Controller Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Piece

About Metravi DTC 200 Single Channel Temperature Controller

- Flush Mounting type

- Sizes 96 x 96 mm sq OR 72 x 72 mm sq

- Display

- 3-1/2 Digits Seven Segment Red

- LED display

- Cold Junction Compensation Automatic forThermocouple

- Open Sensor Indication

- Sensor Input J, K, R, S, T/C, PT-100 RTD, V & 4 20mA

- Accuracy J,K 1%; R,S 0.5%; PT-100 RTD0.2%, mV, V,mA 0.1%

- Hysterisis Pot 1 to 10C for each point for ON OFF Model

- Control Action ON/OFF or Time Proportional

- Control output (options available)

- a. 6A or 20A, 1C/O Relay, 230V.

- b. 12V DC pulse output for SSR for each set point

- Single Set Point

- Auxiliary Power Supply 230V Single Phase AC 50Hz

Versatile Temperature Sensing

The DTC 200 controller accommodates both thermocouple (J, K, T, R, S) and RTD (Pt100) sensors, allowing for broad application across industrial and laboratory settings. Its autodetect feature simplifies sensor setup, ensuring minimal downtime and easy installation.

Accurate and Fast Temperature Control

With a measurement range from -50C to 1999C and an accuracy of 0.5% of full scale, the DTC 200 delivers reliable temperature regulation. Its fast sampling rate (4 samples/sec) and PID control mode allow for rapid response and stable performance, making it suitable for sensitive processes.

User-Friendly Operation

The device features dual LED displays (red for PV and green for SV), offering clear visibility of current and set temperatures. Its single setpoint, programmable alarm, and compact design support straightforward integration and operation in a variety of control panels.

FAQ's of Metravi DTC 200 Single Channel Temperature Controller:

Q: How does the Metravi DTC 200 detect and handle different types of sensors?

A: The DTC 200 is equipped with an autodetect feature, allowing users to select between various thermocouple types (J, K, T, R, S) or RTD (Pt100) sensors. This ensures seamless compatibility and easy switching between sensor types without the need for manual recalibration.Q: What is the main benefit of the PID control mode in this temperature controller?

A: PID (Proportional-Integral-Derivative) control mode enables highly precise temperature regulation by continuously adjusting the control output, minimizing temperature fluctuations and overshoot. This ensures stable operation in critical industrial and laboratory processes.Q: When should the programmable alarm output be used?

A: The programmable alarm output is ideal for situations where immediate notification of temperature deviations is essential. It can be configured to activate when the process value exceeds or falls below set thresholds, helping operators to react promptly to abnormalities.Q: Where can the DTC 200 temperature controller be installed?

A: The DTC 200 is designed for panel mounting, utilizing a cutout size of 92 x 92 mm. This allows it to be easily integrated into control panels in industrial automation systems, laboratory equipment, or other process control applications.Q: What is the process for setting the single setpoint on this controller?

A: To set the single setpoint, users simply use the front-mounted controls to input the desired temperature on the green SV (Set Value) display. The controller will automatically maintain the process value (PV) at or near this setpoint using its PID algorithm.Q: How does the dual display enhance user experience?

A: The dual 7-segment LED displays (red for process value, green for set value) provide immediate, clear visual feedback, allowing users to quickly monitor both the current temperature and the target setting at a glance, improving usability and reducing the risk of error.Q: What type of applications benefit most from the DTC 200?

A: Applications requiring precise and reliable temperature control, such as industrial ovens, plastic manufacturing equipment, laboratory automation, and general process automation, are ideal for the DTC 200. Its robust features and versatile sensor compatibility make it especially beneficial in these environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Meter Category

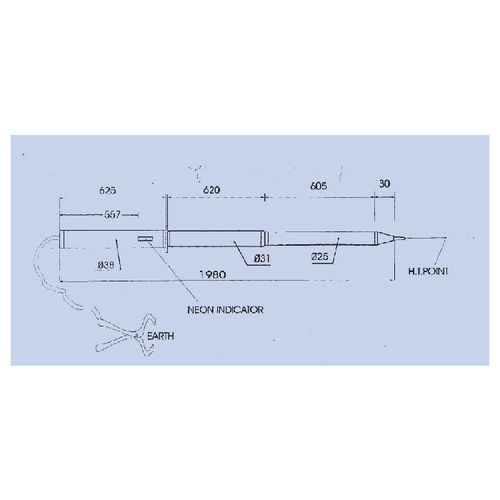

Metravi 33kV Hot Line Indicator

Price 13393.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Shockproof, Lightweight, Portable, Weatherproof housing

Resolution : nan

Power Supply : 9V DC battery

Application : Live Line Detection for Overhead Transmission Lines

Metravi PRO 589 Digital Multimeter TRMS with Bluetooth Support

Price 22597.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : TRMS, Bluetooth connectivity, Data Hold, NCV detection, Dual Display, Flashlight, Auto/Manual Range, Max/Min/Average, Low Battery Indication, Relative Measurement, TrueRMS, Auto Power Off

Resolution : Max 0.01A (Current), 0.1mV (Voltage), 0.01 (Resistance)

Power Supply : 9V battery (6F22) or USB (optional)

Application : Electrical and Electronic measurements, industrial and field use

Metravi 5050E Analogue Multimeter

Price 3835.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Overload Protection, Mirrored Scale, Robust Casing, Multiple Functions

Resolution : Analogue Scale

Power Supply : Battery (1.5V AA x 2)

Application : Electrical and Electronic Measurement

Metravi GM-197 Magnetic Field Gauss Tester

Price 27317.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Portable, LCD Display, High Precision

Resolution : 1 Gauss (0.1 mT)

Power Supply : 9V Battery

Application : Measurement of DC/AC Magnetic Fields, Laboratory, Industrial Field Testing

|

METRAVI INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry